When it comes to mov varistor testing, there are a few simple steps to follow. Firstly, ensure you have the necessary equipment, such as a multimeter and a power source. Disconnect the MOV from the circuit and check for any damage or signs of wear on the MOV core. Next, hook up the multimeter in parallel with the MOV, ensuring the correct polarity. Apply a gradual voltage to the MOV using the power source and monitor the multimeter for any changes in resistance. If the MOV conducts and allows current to pass, it is functioning properly. Remember, it is always recommended to refer to the specific guidelines provided by the metal oxide varistor manufacturer for accurate testing procedures. Testing MOVs is crucial to ensure reliable performance and protection from voltage surges for devices, power systems, and MOV blocks in various applications.

If you are wondering how to test mov varistor with multimeter, we have got you covered. The process involves a few simple steps. First, ensure the power supply to the MOV is disconnected. Set your multimeter to the resistance mode, typically indicated by the ohm symbol (Ω). Connect the multimeter leads to the terminals of the MOV. A functioning MOV should display a very high resistance reading on the multimeter. If the resistance is extremely low or close to zero, it indicates a short-circuited or damaged MOV that needs to be replaced. Checking MOVs using a multimeter is a quick and effective way to assess their functionality and ensure the protection of your electronics from voltage surges.

1.1 D.C. Reference Voltage Test U1mA; Sample #: (A1~A10)

1.2 Leakage Current Test IL at 0.75 U1mA; Sample #: (A1~A10)

1.3 Discharge Voltage Test IR 10kA at 8/20µs; Sample #: (A1~A10)

1.4 2000µs Rectangular Wave Impulse Current Withstand Test; Sample #: (A1~A5)

1.5 High Current Impulse Withstand Test; Sample #: (A6~ A10)

1.6 Accelerated Aging Test

1.7 Each Block Passed Two Times 2000μs Impulse Withstand Test

1.8 Power loss Test: Each Block Conducts power loss test; Sample #: (A1~A10)

Test Item of Metal Oxide Arrester Blocks

For

IEC 60099-4

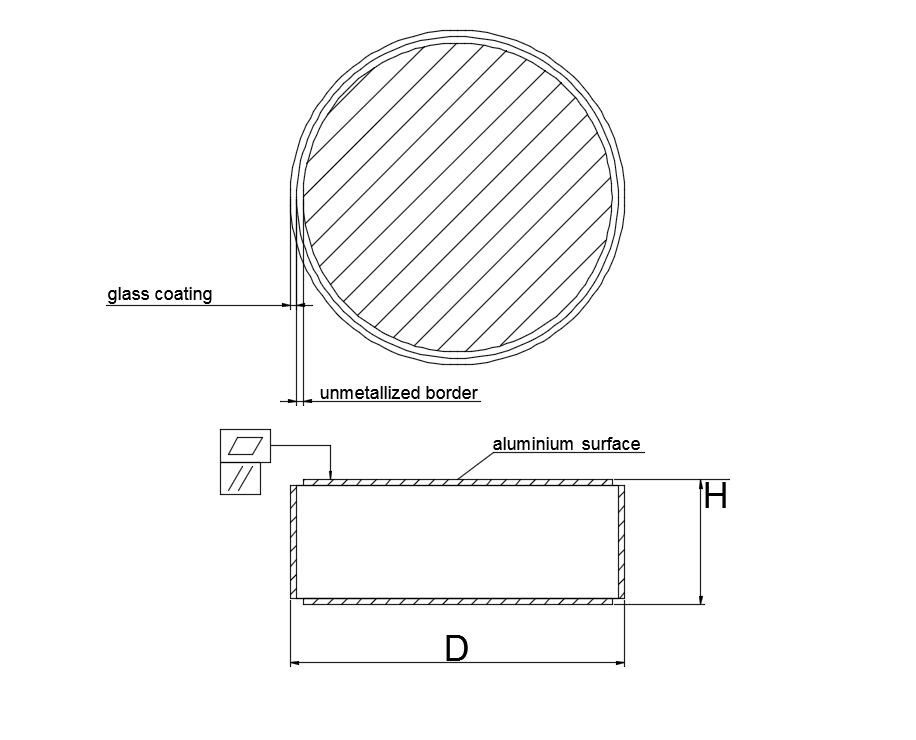

Refer to below diagram.

Diameter: 69.0 ~ 71.0 mm

Height: 20.8 ~ 22.0 mm

Unmetallized border: 0.0 ~ 0.5 mm

Parallelism: ≤ 0.1 mm

FlatnessL: ≤ 0.05 mm

Samples for test: 10pcs per lot

Criterion: all 10pcs within specification

We will do 100% routine test for below items.

1)2ms routine test,

First test: 2 impulses and 850A, impulse interval 50 ~ 60s

Second test: 2 impulses and 850A, impulse interval 50 ~ 60s

In case the failure rate is higher than 6 %, the routine test has to be repeated so often, until the failure rate is lower than 6 %.

2)Power loss at Ures /3.0 and 25℃.

3)Lightning residual voltage at 10kA.

4)Readability test of Data matrix-2D code.

3.1 U10kA / U1mA (S7)

Measure lightning residual voltage at 10kA with 8/20µs waveshape, measure DC voltage at 1mA, then calculate the ratio of lightning residual voltage at 10kA and DC voltage at 1mA.

Requirement: U10kA / U1mA ≤ 1.68

Samples for test: 6pcs per lot

Criterion: all 6pcs within specification

3.2 Ures / Uref

Measure lightning residual voltage at 10kA with 8/20µs waveshape, measure AC reference voltage at peak value of resistive current 5mA, then calculate the ratio of lightning residual voltage at 10kA and AC reference voltage at 5mA.

Requirement: Ures / Uref ≤ 2.23

Samples for test: 6pcs per lot

Criterion: all 6pcs within specification

3.3 Power loss at 190℃

Measure power loss at 190℃ under AC test voltage Ures/3.0.

Requirement: P190℃ ≤ 14.0 W

Samples for test: 6pcs per lot

Criterion: all 6pcs within specification

3.4 2ms repetitive charge transfer test

20 impulses with rectangular 2ms waveshape at charge rating 1.6 C, 20 impulses are divided into 10 groups, each group 2 impulses. Impulse interval 50 ~ 60s in group and cool down to ambient temperature between groups. Applying 1 more impulse of 8/20µs at 20kA after repeating Ures measurement.

Charge value for test: 1.76 C*Ures,upper limit / Ures, actual

Requirements: no flashover outside, no crack, no puncture.

change of Ures ≤ 5%

change of Uref ≤ 5%

withstand 1 more impulse of 8/20µs at 20kA

Samples for test: 5pcs per lot

Criterion: all 5pcs pass the test. If not more than 1pcs fail the test, then repeat the test with other 5pcs, it pass the test if no further failure, it fail the test if still failure.

3.5 4/10µs high current test

2 impulses with waveshape 4/10µs at 100kA, cool down to ambient temperature before 2nd impulse. Applying 2 more impulses of 2ms at 850A after 4/10µs test and repeating power loss test.

Requirements: no flashover outside, no crack, no puncture.

Pcov,after test / Pcov, initial ≤ 1.8

withstand 2 more impulses of 2ms at 850A

Samples for test: 2pcs per lot

Criterion: both 2pcs pass the test

3.6 Accelerated AC ageing test

The test is under 115℃, 0.90* Uref and N2 or dry air. Perform 1000h test for type test and 200h test for lot release test.

Requirements: power loss shows permanent decreasing trend or be stable after initial decreasing.

Samples for type test: 3pcs

Samples for lot test: 2pcs per lot

Criterion: Both parts pass the test

3.7 Partial discharge test

Partial discharge < 2 pC at 1.05*Ures/3.0, test procedure according to IEC60099-4.

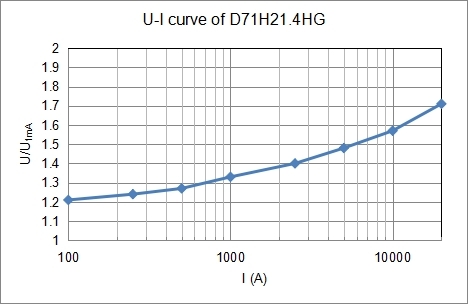

Typical U~I curve of D71H21.4HG is illustrated as below diagram. 100A to 500A are with 30/60µs and 1kA to 20kA are with 8/20µs.

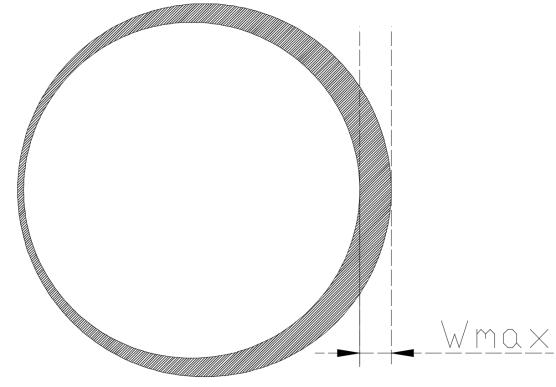

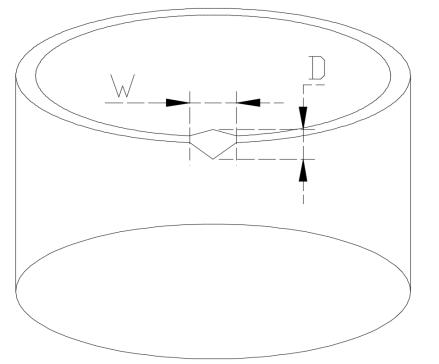

We will do 100% appearance check, below parts are not accepted and will not be delivered:

1) Aluminum on the lateral surface.

2) Width of the unmetallized border is bigger than 0.5mm, refer to diagram a.

3) Chips up to aluminum metallization.

4) Depth and width of the chip should be within the below table, refer to diagram b.

depth of chip | width of single chip | width of total chips |

≤ 1.5 mm | ≤ 2.0 mm | ≤ 5.0 mm |

Welcome to TGE's Customer Connect Center. Experienced specialists are here for you 365 days a year.

No.53, Hong Guang Road, He Ping Industrial Park, San Qiao, Xi'an, China.